Gas Detection That Meets the Realities of Industrial Safety

In industries where air quality and personnel safety are critical, accurate gas detection is essential—not just for compliance, but for operational continuity and worker health. ION SENSE®, a brand of ION Science Limited, has developed a suite of gas sensing and integration tools designed to support these frontline needs.

Meeting the Demands of High-Risk Workplaces

Gas detection systems must be responsive, reliable, and simple to deploy. ION SENSE®’s portfolio addresses these needs with proven sensing technologies tailored for use in complex industrial and occupational environments—where conditions can vary widely and precision is non-negotiable.

The ION SENSE® PID is engineered for the detection of volatile organic compounds (VOCs), offering a 50% faster response time, enhanced EMI protection, and long-life components that reduce maintenance burdens. Intelligent diagnostics help users identify potential issues before they impact operations. Its performance remains consistent even in high-humidity, contaminating, or confined-space scenarios.

Supporting Health & Safety Compliance Through Real-Time Monitoring

The MiniPID 2 series of sensors is a workhorse for environments where VOC exposure needs to be continuously monitored in a wide range of environmental conditions. It’s frequently applied in sectors such as:

- Industrial hygiene and workplace exposure

- Environmental health and safety assessments

- Indoor and outdoor air quality monitoring

Models in the MiniPID 2 series are built to address different detection requirements:

- MiniPID 2 HS – for sub-PPB detection

- MiniPID 2 PPB – for ultra-low concentrations

- MiniPID 2 WR – for wide-range measurement

- MiniPID 2 10 eV – for detecting Benzene, Toluene, Ethyl Benzene and Xylene (BTEX)

Each is compatible with diffusive or pumped sampling, making them adaptable to mobile, fixed, or wearable applications. The robust design and low power consumption support continuous use—even in remote or battery-dependent deployments.

Accurate Particulate Matter Detection in Challenging Conditions

Airborne particles are a growing concern in both indoor and outdoor industrial spaces. The NextPM Particulate Matter sensor offers real-time direct monitoring of PM₁, PM₂.₅, and PM₁₀. Built with patented airflow and humidity control and a dual-angle optical system, it maintains measurement accuracy even in environments with fluctuating conditions, extreme humidity and high particulate loads.

It’s an effective tool for safety officers tasked with monitoring air quality in manufacturing zones, laboratories, construction sites, and urban settings.

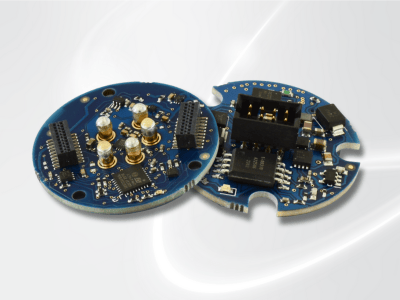

Integration Tools to Streamline System Development

For teams developing or upgrading monitoring systems, ION SENSE® provides integration-ready hardware that eliminates the need for complex circuitry:

- ION CONNECT – Digitises analogue PID data (via UART and I²C) for quick interpretation

- ION TRANSMIT – Enables remote long-range communication with industry standard protocols (MODBUS RTU, 4–20 mA)

Both solutions are compact, configurable, and suitable for use in a variety of form factors, from stationary enclosures to portable instruments. Built-in diagnostics and flexible output reduce development time and long-term maintenance.

A Practical Approach to Safer Operations

Whether supporting compliance with occupational exposure limits or enabling early warning for toxic gas and particle event, ION SENSE® technology is focused on delivering accurate data, low overhead, and reliability in tough environments.

Evaluation kits are available to support trial deployments or integration testing.

For more information contact sensors@ionsense.com.